SIECO ENGINEERS P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SIECO ENGINEERS P.LTD.

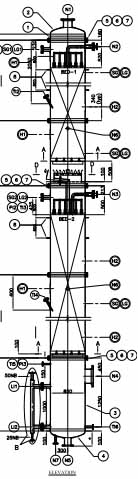

Seam Welders

Seam welding is resistance welding or roller welding process for joining metal sheets / seam joints between two rotating electrode wheels performed using electrical current which is passed through a lid and container. As the metal heats up, the lid is completely joined to the body of the container. Seam Welding is high speed and clean process, which is used when continuous tight weld is required. Seam Welding is mainly used on the seams of tubes and pipes for its ease and accuracy. Seam welding is used to create larger flat-stock parts, join relatively long components, and create cylinders, cones etc.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.